Rollcage

With my regular trips to the steep Tellico mountains and nasty Paragon trails, I had to get better protection than the stock 'sport cage'.

Although most people say using tube over pipe is the only way to go, it is much more expensive, especially for the tube bender. My line of thinking is anything above stock is better than nothing, so I went with pipe. Besides, the most likely situation where I'll need the cage is in a slow roll on the trail, where the pipe will be more than sufficient.

So on to my pipe rollcage. I went with 1.5" schedule 40 pipe, which is 1.9" outside diameter and 0.145" wall. I decided to build a new front section and keep the stock rollcage from it's main hoop back. Another thing that isn't recommended but I did anyways was to bolt the front part of the cage to the stock cage. Having the cage in two pieces makes it a lot easier to remove, especially if I want to pull back my dash.

For the outside bars I welded the end of the stock side bars inside the pipe and reused the same bolt hole in the corners of the stock cage.

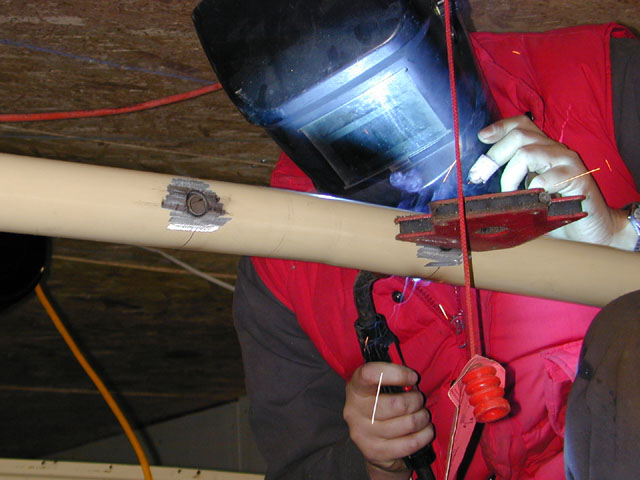

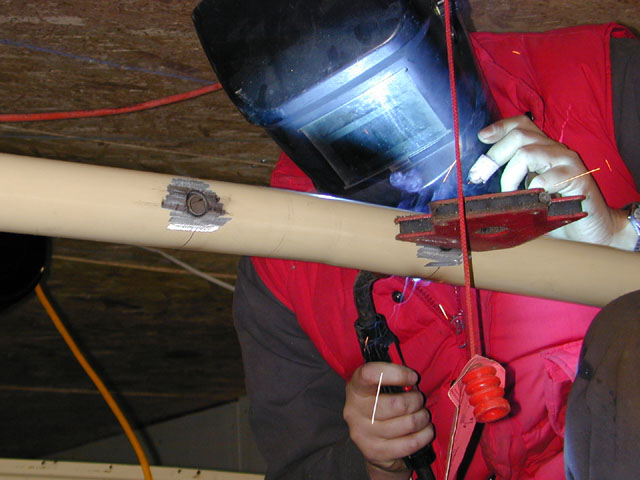

For the inner top bars, I had to drill holes and weld in some tubes as bolt guides into the stock hoop.

On the back of the tube, I welded on some washers to give the bolt head a flat surface.

There are differing views wether the cage should be attached to the body only or down to the frame. Attaching to the frame is stronger, but requires bushing mounts to keep the frame flex, and the body must remain attached to the frame in a rollover. Otherwise you're better off with the cage attached to the body only and going for a ride inside the body/cage.

Either way, the cage must have a good connection to the body. I used two 3/16" plates. The one on top (insed the body) is larger than the one on the bottom. This is to spread the stress points on the floor sheet metal and prevent cutting it. The bottom plate is strong enough I could use it to attach the cage to the frame at a later date. One other thing I should have done is gring the corners round, again to prevent the plates from cutting through the floor.

To strenghten the main hoop I installed a cross bar.

Finally I bent some 1/2" pipe to a 90' angle using an oversized die to get a larger radius. These I used for handles. I put handles on the outside bars and the top inner bars. But after installing the cage and sitting in my Jeep, I noticed I could easily smack my head on the top ones, so I had to remove them. The final touch was some thick roll bar padding from a race shop.

Long after building my cage I found this good website. Have a look at it if you're planning on building your own, and ignore that he's recommending a pipe bender as a tube bender, experience has shown you do need a tube bender for tube.

Back to mods page.