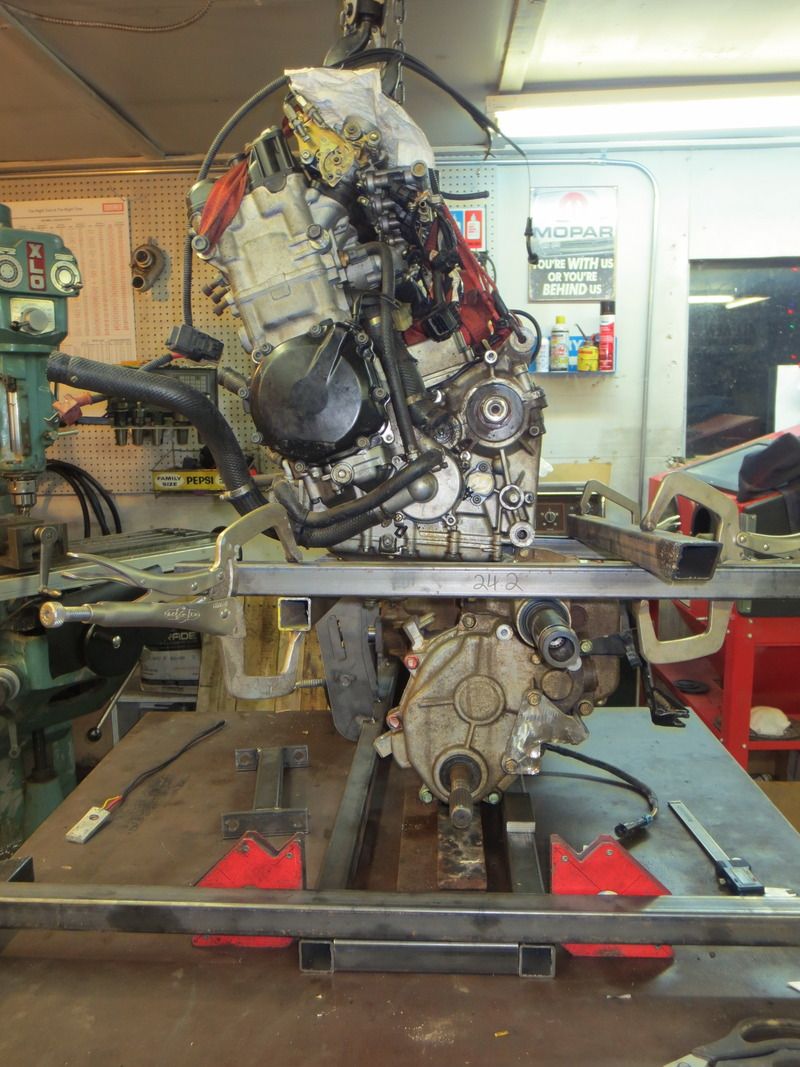

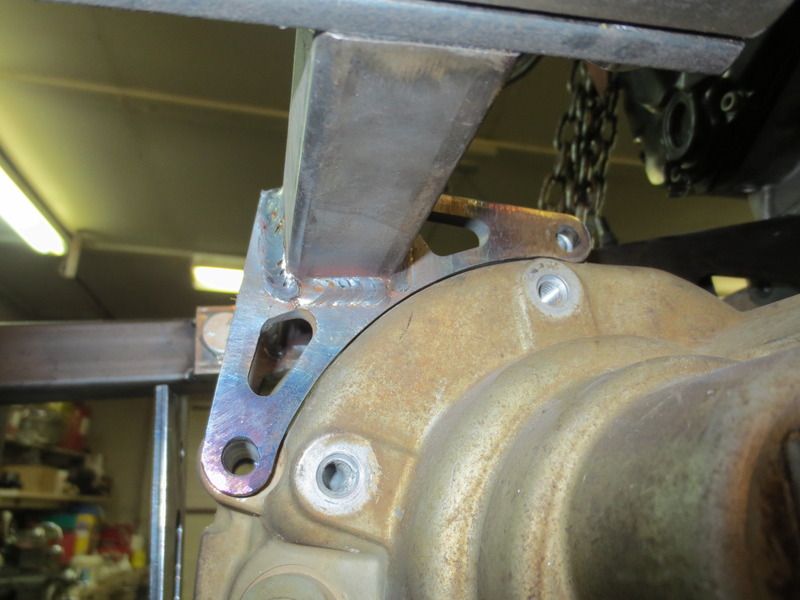

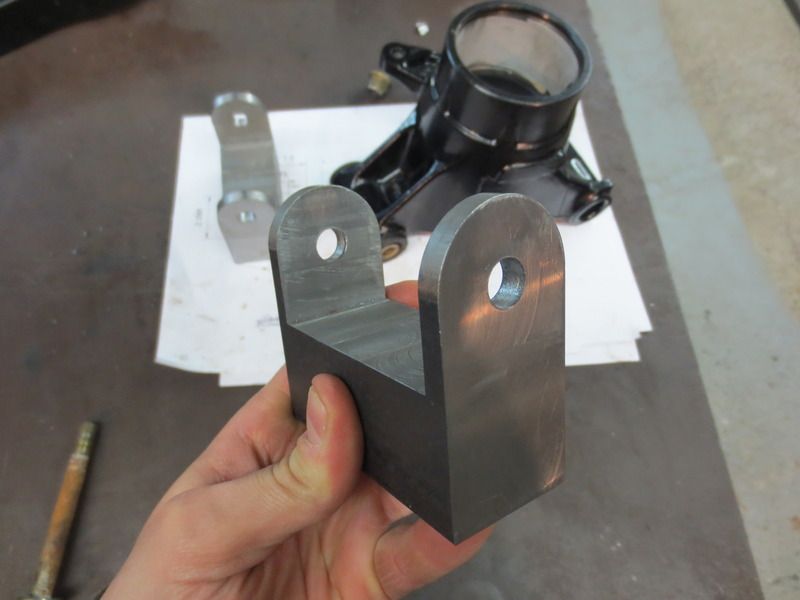

I thought some local folks would enjoy my latest project. I've build dune buggies before, but this is the first 4wd multi-passenger machine that I've ever tackled. The drive-train is from a 2009 RZR 800 and the engine is a 2002 Suzuki GSXR 600 street bike. I'll be running 30" 8 ply tires, 12" ground clearance, and 14" of suspension travel. The frame is completely designed by me in 3d CAD (Sketchup) and will used square tube on the bottom section of the frame and 1.5" round tube for the roll...

Please login to view full content. Log in or register now.