You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Project - The Excessive Closet Juggy

- Thread starter blueguy

- Start date

blueguy

Jackstand Racer

Ok, so took it to get some poseur flex shots and see how the suspension works, and it would seem that to take pictures with a digital camera, one would need batteries in said camera :flipoff:

In any case, without getting too crazy with the rig (but yet having a small motorcade of VIP's drive right by :stir: ), the suspension seems to work great, although I'm leaning more towards a sway bar at this point unless I'm proven wrong when I actually get to wheel it.

Couple bad points from tonight's excursion:

1) The oil pressure sender leaks a bit from the base. Gonna need to re-tape that. It seems too that either the oil pan leaks or the rear main leaks - I have motor oil dripping from the tranny inspection cover. Not a big deal, the motor will be rebuilt and stroked when I get back;

2) The Cherry Bomb is definitely WAY too loud. I think I'm going to go to a conventional muffler with a bit more exhaust tube (the CB has about 2' of exhaust between it and the headers) to try and get it back toward the conventional location;

3) When I backed it back into my driveway tonight, the tranny temp was sitting around 200*F or so, with the fan going full blast on the tranny cooler. When I pulled the dipstick, it was showing full, and there are no leaks anywhere. I'm hoping that this is just something that is normal with freshly-rebuilt slushboxes, or maybe the temp just spiked a little when I finished driving. Either way, it's deinitely something I will have to keep an eye on.

All in all, so far I'm pretty happy with how it turned out, I just need time to finish off the little stuff that remains and get it out onto the trail :smokin:

In any case, without getting too crazy with the rig (but yet having a small motorcade of VIP's drive right by :stir: ), the suspension seems to work great, although I'm leaning more towards a sway bar at this point unless I'm proven wrong when I actually get to wheel it.

Couple bad points from tonight's excursion:

1) The oil pressure sender leaks a bit from the base. Gonna need to re-tape that. It seems too that either the oil pan leaks or the rear main leaks - I have motor oil dripping from the tranny inspection cover. Not a big deal, the motor will be rebuilt and stroked when I get back;

2) The Cherry Bomb is definitely WAY too loud. I think I'm going to go to a conventional muffler with a bit more exhaust tube (the CB has about 2' of exhaust between it and the headers) to try and get it back toward the conventional location;

3) When I backed it back into my driveway tonight, the tranny temp was sitting around 200*F or so, with the fan going full blast on the tranny cooler. When I pulled the dipstick, it was showing full, and there are no leaks anywhere. I'm hoping that this is just something that is normal with freshly-rebuilt slushboxes, or maybe the temp just spiked a little when I finished driving. Either way, it's deinitely something I will have to keep an eye on.

All in all, so far I'm pretty happy with how it turned out, I just need time to finish off the little stuff that remains and get it out onto the trail :smokin:

blueguy

Jackstand Racer

A little update:

So one day while sitting in the desert staring off into the distance watching a local mess around with his very obviously broke-down truck, I got to thinking that while I am home for my 3 weeks off in Feb, I should start doing the legwork so I can get my motor stroked when my trip is over in May. I had originally intended to rebuild the engine myself (minus the machining of course), but in order to avoid another summer of my rig sitting in the garage collecting dust, my legwork turned into "Hey, I should get it pulled, stripped down, and dropped off so that it is ready when I get home in May" :stir:

Being that I really don't have a whole lot to do while the Mrs is at work during the day (and not many "Honeydoo" lists), I wanted to make this project last a bit:

Day 1: Drank Tim Horton's, drained the coolant and removed the air cleaner & mixer assembly:

Day 2: Drank Tim Horton's, unhooked the electrical and removed the distributor. Drank more Tim Horton's.

Day 3: Drank Tim Horton's, unbolted the torque converter & tranny from the motor, and removed the PS pump (keeps me from having to refill / rebleed it ).

).

Day 4: Drank Tim Horton's, unbolted the motor mounts from the frame and hauled the motor out:

I never really realized how busy my engine compartment was until I looked down after the motor was out:

When I started building the Juggy, I invested in one of those collapsible 2 ton cherry pickers that PA sells that has an attachable engine stand. Nothing like just having to drop an attachment onto the cherry picker and being able to bolt a motor to it :smokin:

As I was ready to call Day 4 (or should I say morning?) a wrap , I could hear this little voice calling to me - "come on, you cannot be serious - you're going to leave this sitting here and there is still half a day left..." :stir:

3 hours and a couple more coffees later, I had the engine pretty close to completely stripped down and ready to load into my tow rig to take down to the machine shop here in town:

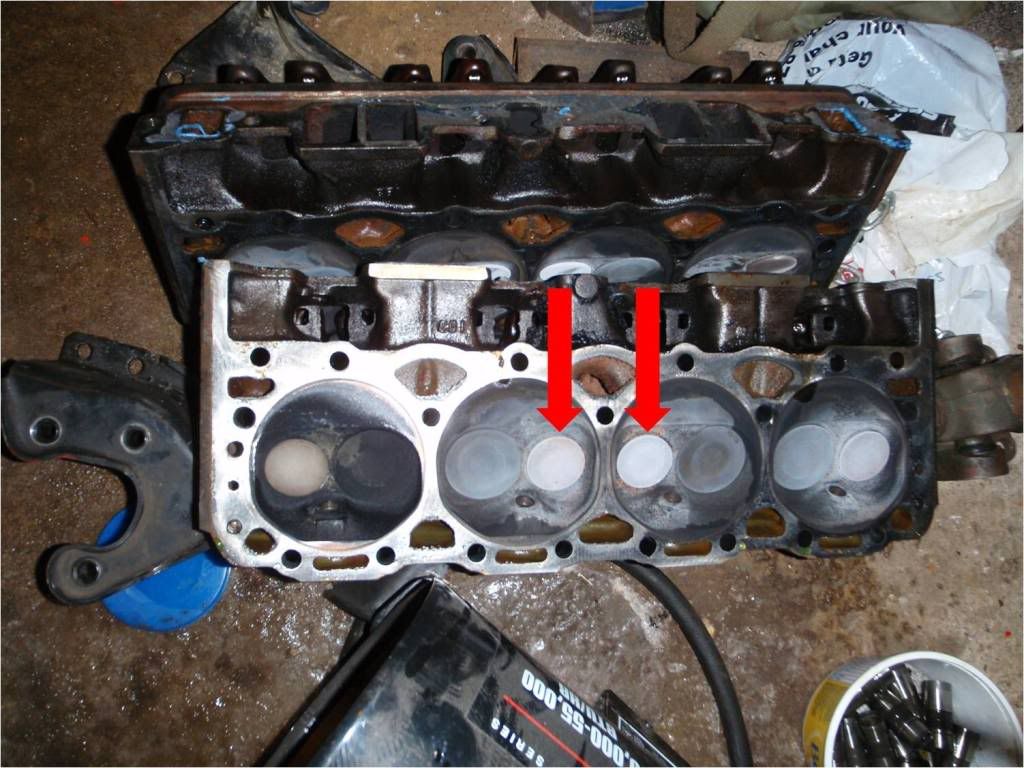

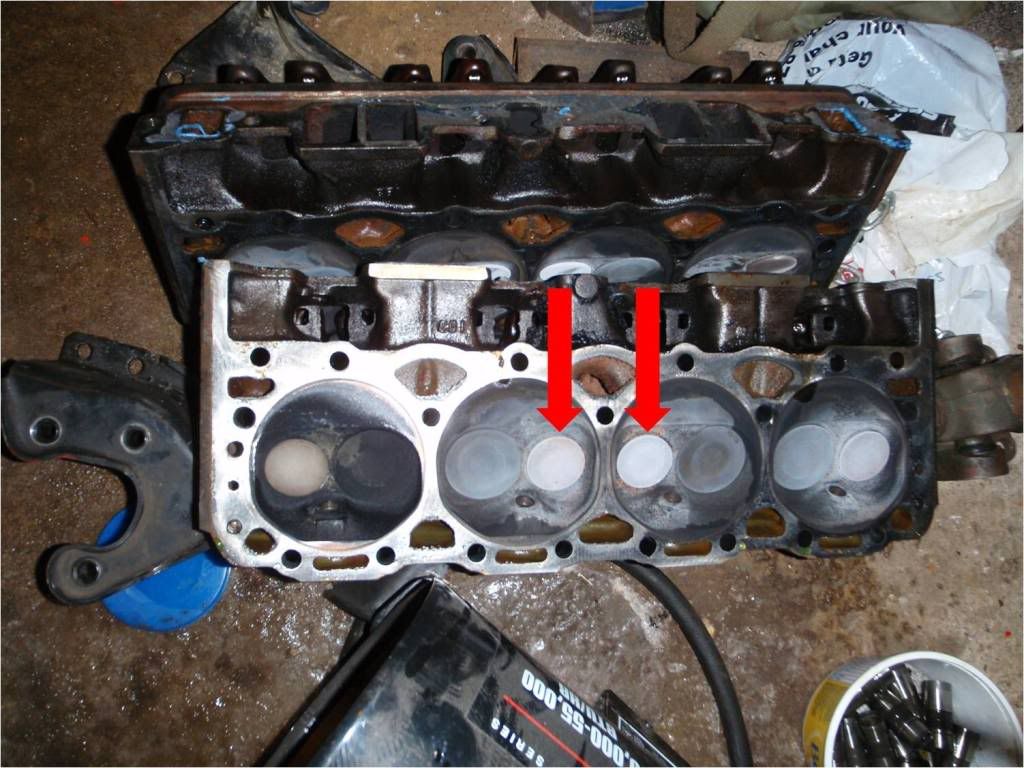

It would appear that the rings in cylinder #2 weren't sealing all that well or the head gasket was going, as the piston had a bit of oil built up on it, as did the valves. All 8 cylinder walls had pronounced ridges and the coolant passages in both the block and heads had gunk in them, but other than that and what appears to be dirt in the lifter valley, the motor looks to be in great shape.

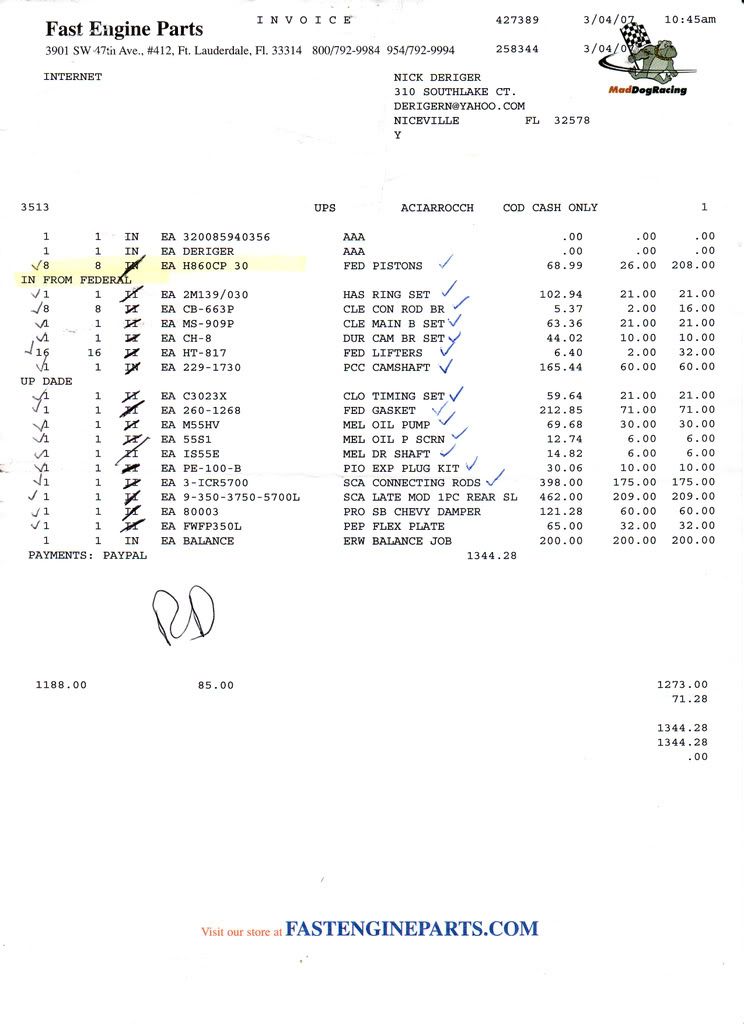

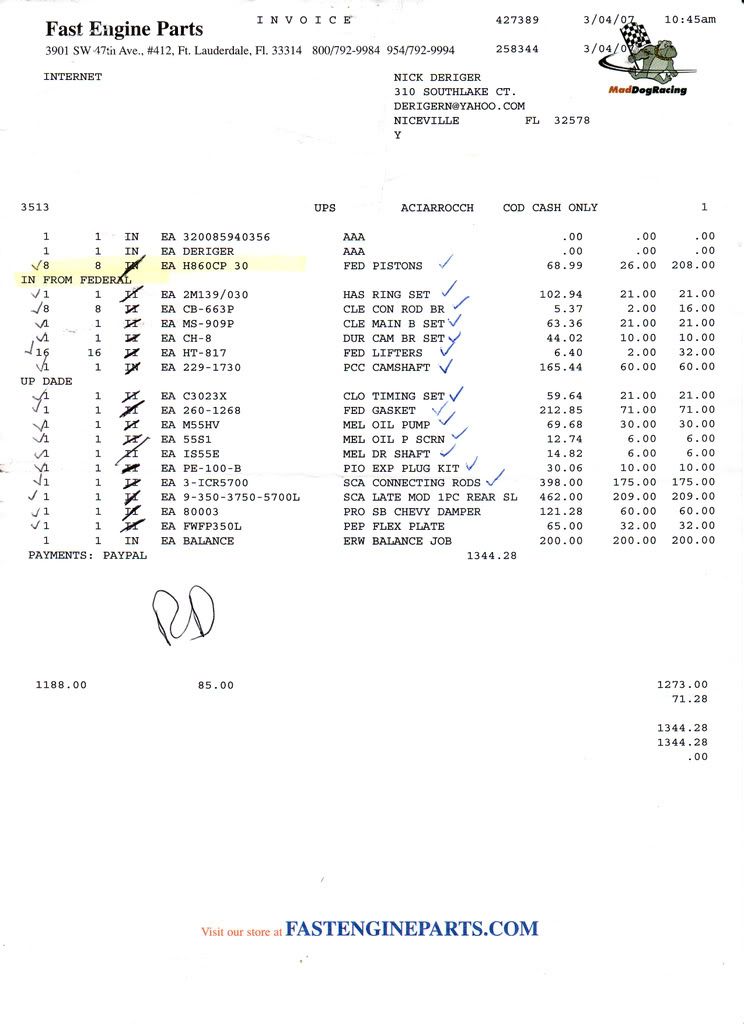

The 383 rotating assembly I bought while in Florida turned out to be pretty complete. For less than what the nearest comparable kit costs on Summit?s site (and with more parts), I got a complete rotating assembly including cam and bearings, and all gaskets:

I took a chance and got the kit from Fast Engine Parts on Ebay as they were pretty close to where I was staying in Florida - http://stores.ebay.ca/Maddog-Racing...W0QQcolZ2QQdirZQ2d1QQfsubZQ2d33QQftidZ2QQtZkm . I had the kit within a week or so, and that was including balancing. It appears the only thing this kit doesn?t include is a new set of push rods.

When I got the engine torn down, I searched the head casting numbers to get an idea of combustion chamber size. The casting number off this set of heads is 14102193, which according to Mortec.com are '87-up 305/350 heads with 1.94"/1.5" valves.

After a little Googling, it would seem that these heads are '87 - '95 swirl port TBI truck heads, with a 65.3 cc combustion chamber. Depending on the poster and which site visited, these are either half decent heads for low-end power and fuel economy or the worst heads on the face of the earth. That being said, the guy at the machine shop has recommended aluminum heads for a propane engine mostly due to their heat dissipation properties, lighter weight and combustion chamber shapes. I guess a little more research is in order :clue: Anyone have any suggestions that aren't $1200 / head?

I feel like a kid knowing Christmas is just around the corner, and cannot wait to get back in May to get this installed and take my rig for its maiden wheeling voyage :smokin:

So one day while sitting in the desert staring off into the distance watching a local mess around with his very obviously broke-down truck, I got to thinking that while I am home for my 3 weeks off in Feb, I should start doing the legwork so I can get my motor stroked when my trip is over in May. I had originally intended to rebuild the engine myself (minus the machining of course), but in order to avoid another summer of my rig sitting in the garage collecting dust, my legwork turned into "Hey, I should get it pulled, stripped down, and dropped off so that it is ready when I get home in May" :stir:

Being that I really don't have a whole lot to do while the Mrs is at work during the day (and not many "Honeydoo" lists), I wanted to make this project last a bit:

Day 1: Drank Tim Horton's, drained the coolant and removed the air cleaner & mixer assembly:

Day 2: Drank Tim Horton's, unhooked the electrical and removed the distributor. Drank more Tim Horton's.

Day 3: Drank Tim Horton's, unbolted the torque converter & tranny from the motor, and removed the PS pump (keeps me from having to refill / rebleed it

Day 4: Drank Tim Horton's, unbolted the motor mounts from the frame and hauled the motor out:

I never really realized how busy my engine compartment was until I looked down after the motor was out:

When I started building the Juggy, I invested in one of those collapsible 2 ton cherry pickers that PA sells that has an attachable engine stand. Nothing like just having to drop an attachment onto the cherry picker and being able to bolt a motor to it :smokin:

As I was ready to call Day 4 (or should I say morning?) a wrap , I could hear this little voice calling to me - "come on, you cannot be serious - you're going to leave this sitting here and there is still half a day left..." :stir:

3 hours and a couple more coffees later, I had the engine pretty close to completely stripped down and ready to load into my tow rig to take down to the machine shop here in town:

It would appear that the rings in cylinder #2 weren't sealing all that well or the head gasket was going, as the piston had a bit of oil built up on it, as did the valves. All 8 cylinder walls had pronounced ridges and the coolant passages in both the block and heads had gunk in them, but other than that and what appears to be dirt in the lifter valley, the motor looks to be in great shape.

The 383 rotating assembly I bought while in Florida turned out to be pretty complete. For less than what the nearest comparable kit costs on Summit?s site (and with more parts), I got a complete rotating assembly including cam and bearings, and all gaskets:

I took a chance and got the kit from Fast Engine Parts on Ebay as they were pretty close to where I was staying in Florida - http://stores.ebay.ca/Maddog-Racing...W0QQcolZ2QQdirZQ2d1QQfsubZQ2d33QQftidZ2QQtZkm . I had the kit within a week or so, and that was including balancing. It appears the only thing this kit doesn?t include is a new set of push rods.

When I got the engine torn down, I searched the head casting numbers to get an idea of combustion chamber size. The casting number off this set of heads is 14102193, which according to Mortec.com are '87-up 305/350 heads with 1.94"/1.5" valves.

After a little Googling, it would seem that these heads are '87 - '95 swirl port TBI truck heads, with a 65.3 cc combustion chamber. Depending on the poster and which site visited, these are either half decent heads for low-end power and fuel economy or the worst heads on the face of the earth. That being said, the guy at the machine shop has recommended aluminum heads for a propane engine mostly due to their heat dissipation properties, lighter weight and combustion chamber shapes. I guess a little more research is in order :clue: Anyone have any suggestions that aren't $1200 / head?

I feel like a kid knowing Christmas is just around the corner, and cannot wait to get back in May to get this installed and take my rig for its maiden wheeling voyage :smokin:

Farm Boy

Bought the Farm

A little update:

Day 1: Drank Tim Horton's,

Day 2: Drank Tim Horton's, Drank more Tim Horton's.

Day 3: Drank Tim Horton's,

Day 4: Drank Tim Horton's,

:smokin:

I think I'm going to like wheeling with you. :glasses:

R

Root Moose

Guest

After a little Googling, it would seem that these heads are '87 - '95 swirl port TBI truck heads, with a 65.3 cc combustion chamber. Depending on the poster and which site visited, these are either half decent heads for low-end power and fuel economy or the worst heads on the face of the earth. That being said, the guy at the machine shop has recommended aluminum heads for a propane engine mostly due to their heat dissipation properties, lighter weight and combustion chamber shapes. I guess a little more research is in order :clue: Anyone have any suggestions that aren't $1200 / head?

The thing about those heads is that it is all about expectation levels. If you are going for quarter mile times they will suck. If they are going into a truck then not so much.

I'm not up on propane and I'm a little fuzzy on what I read about aluminum heads but IIRC when switching to Al heads ideally you want smaller combustion chambers because the aluminum does something that effectively drops the compression ratio. It doesn't numerically/physically of course, but the effective result due to the material and the heat soaking capabilities means that it is like the CR has dropped when comparing Al to Fe heads of the same chamber size. You can get away with more compression with Al heads or conversely you can setup for more compression via a milled smaller chamber - if that makes sense.

For heads - used Vette L98s and such are affordable. Why set on Al? For a car I could see it but for a Jeep, that ~40lbs you'll be saving in weight will not be noticed. You can research till you're blue in the face over at thirdgen.org. I have the same "eco" swirl port heads on my engine. I still haven't settled on which heads other than junk yard Fe heads. Thinking about Vortecs. The weight difference for Al isn't worth the hassle IMO and Fe block with Fe heads will tolerate overheating better if something should happen. For a Jeep that is my logic.

blueguy

Jackstand Racer

I think I'm going to like wheeling with you. :glasses:

Tim's makes my world go 'round

Those guys from Petawawa don't wheel!!! They just build big ass trucks for a hobby!!!

Hope you get it out this year! Let me know when your ready to tune those shox!

:beer::beer:

You're killing me John :flipoff:

If work would stop getting in the way of my hobbies, this thing would have been done two years ago :baby:

I'll definitely be giving you a ring in May when it's tune time :smokin:

The thing about those heads is that it is all about expectation levels. If you are going for quarter mile times they will suck. If they are going into a truck then not so much.

I'm not up on propane and I'm a little fuzzy on what I read about aluminum heads but IIRC when switching to Al heads ideally you want smaller combustion chambers because the aluminum does something that effectively drops the compression ratio. It doesn't numerically/physically of course, but the effective result due to the material and the heat soaking capabilities means that it is like the CR has dropped when comparing Al to Fe heads of the same chamber size. You can get away with more compression with Al heads or conversely you can setup for more compression via a milled smaller chamber - if that makes sense.

For heads - used Vette L98s and such are affordable. Why set on Al? For a car I could see it but for a Jeep, that ~40lbs you'll be saving in weight will not be noticed. You can research till you're blue in the face over at thirdgen.org. I have the same "eco" swirl port heads on my engine. I still haven't settled on which heads other than junk yard Fe heads. Thinking about Vortecs. The weight difference for Al isn't worth the hassle IMO and Fe block with Fe heads will tolerate overheating better if something should happen. For a Jeep that is my logic.

I will second what Chris is saying about the aluminum heads. Overheating is always an issue when wheeling. Fans go south more frequent in the extreams that we put them through. Also running mud, snow and long switchbacks tend to work an engine harder than at race day. Most track cars don't even see perating temperatures because they only go for 12 second shots. I'd have what you have rebuilt before sinking a ton of money into new heads.

Hmmmm......When I went into the machine shop yesterday to drop off the engine, I told him I wanted to use Vortec heads in the future (nothing like an instant power increase with no mods other than a compatible intake manifold

I'm really a noob at this engine building stuff :banghead: , but I'm thinking that maybe I will carry on with my original plan of having these heads freshened up and see how it runs for this season, and then get a set of Vortec heads for a small winter project next winter to keep me busy for a month :lmao:

I too agree with Chris and John. Also i have heard of guys having problems with head gaskets when running aluminum heads on cast blocks. Aluminum expands and contracts faster than cast so when offroading, expecially when going through water, i have heard of problems with keeping gaskets sealed.

I would just take the stock heads and port/gasket match them. That would be much cheaper then buying aluminum heads, open up a few more ponies plus you could do it yourself.

Matt

I would just take the stock heads and port/gasket match them. That would be much cheaper then buying aluminum heads, open up a few more ponies plus you could do it yourself.

Matt

blueguy

Jackstand Racer

Also I have heard of guys having problems with head gaskets when running aluminum heads on cast blocks. Aluminum expands and contracts faster than cast so when offroading, especially when going through water, I have heard of problems with keeping gaskets sealed.

Hmmmmm.....this never even crossed my mind, although I am pretty sure I have read about these problems before on a couple boards.

Iron heads it is! :beer: (at least until I have a way better understanding of V8 performance mods)

R

Root Moose

Guest

If you still want to do the Vortec heads, do your research on it. IIRC it requires at a minimum changing the intake manifold to a Vortec compatible version (port locations and sizes are slightly different). Spidey-sense is telling me there is something else as well but I'm too caught up in other things (stupid computers!) to go look for you.

Like anything with this hobby, once you start changing one thing it leads to and, and, and...

Run it and get it out the door. Make changes the next winter - if you even need them.

Like anything with this hobby, once you start changing one thing it leads to and, and, and...

Run it and get it out the door. Make changes the next winter - if you even need them.

Last edited:

blueguy

Jackstand Racer

If you still want to do the Vortec heads, do your research on it. IIRC it requires at a minimum changing the intake manifold to a Vortec compatible version. Spidey-sense is telling me there is something else as well but I'm too caught up in other things (stupid computers!) to go look for you.

I do eventually plan on switching to the Vortec heads, although it probably won't be until next winter. I'm pretty sure the only other thing to change is the intake manifold.

Root Moose said:Like anything with this hobby, once you start changing one thing it leads to and, and, and...

No kidding. This little 3 year (going on to 4 years now

blueguy

Jackstand Racer

Got the engine and rotating assembly dropped off this morning in town. The machinist had a quick look through my bin of parts, and seemed quite impressed with how complete the kit was, as well as the quality of parts.

He also pointed out that the stocker heads I brought in already had the hardened valve seats needed to run propane :smokin: Again, he recommended aluminum heads when funds allow.

Another quick guesstimate on his part as to what the total will be once I pick this up was in the neighbourhood of $1200 - $1500, which includes the remainder of the disassembly, hot tanking, magnafluxing, boring and decking the block, refreshing the heads, and assembling the engine using ARP main cap and cylinder head bolts and a set of one piece push rods.

I guess we shall see how close he comes to his quote when I pick this back up in May :glasses:

Someone asked the other day what all came in the kit:

Hopefully the next update will be the reinstallation of the engine and taking the rig out for a shakedown run locally after cam break-in :smokin:

As for me, holiday's over - now back to my day-job

He also pointed out that the stocker heads I brought in already had the hardened valve seats needed to run propane :smokin: Again, he recommended aluminum heads when funds allow.

Another quick guesstimate on his part as to what the total will be once I pick this up was in the neighbourhood of $1200 - $1500, which includes the remainder of the disassembly, hot tanking, magnafluxing, boring and decking the block, refreshing the heads, and assembling the engine using ARP main cap and cylinder head bolts and a set of one piece push rods.

I guess we shall see how close he comes to his quote when I pick this back up in May :glasses:

Someone asked the other day what all came in the kit:

Hopefully the next update will be the reinstallation of the engine and taking the rig out for a shakedown run locally after cam break-in :smokin:

As for me, holiday's over - now back to my day-job

D

Dirk

Guest

nice....makes me wanna build another mill.

R

Root Moose

Guest

Dirk needs to build a Land Cruiser.

Dirk needs to build a Land Cruiser.

I see Sarge has his BJ60 up for sale on JK - already rollin on 35's:stir:

Cheers Jamie:beer:

D

Dirk

Guest

Dirk needs to build a Land Cruiser.

Cruisers are cool... don't rule it out.

blueguy

Jackstand Racer

More update:

Picked up my motor on Wednesday. When I picked it up, I found out that it was a good call on my part to get the machinist to go through the cylinder heads - the centre cylinders on both heads had cracks running from the exhaust valve seats out toward the EGR ports. I didn't bring my camera with me to the machine shop, but the arrows show where they were:

The machinist told me he found another set of the same casting heads and freshened them up for me. The icing on top of the cake was that he didn't even charge me for the replacement heads :smokin:

He even shrink-wrapped the motor to keep it clean:

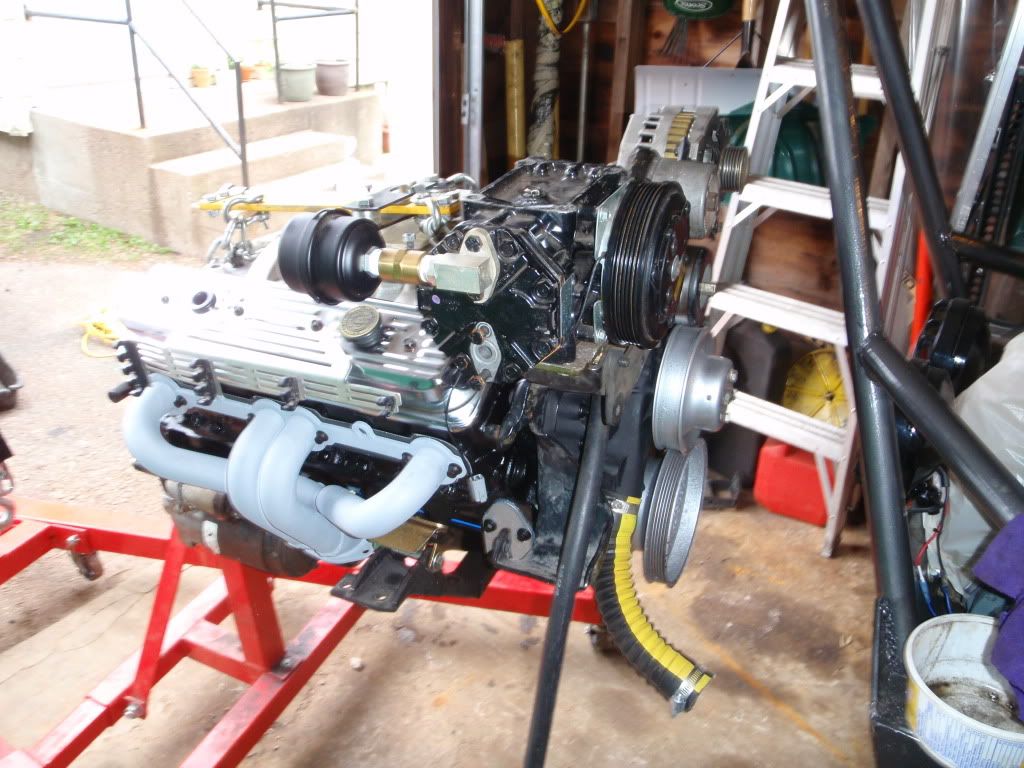

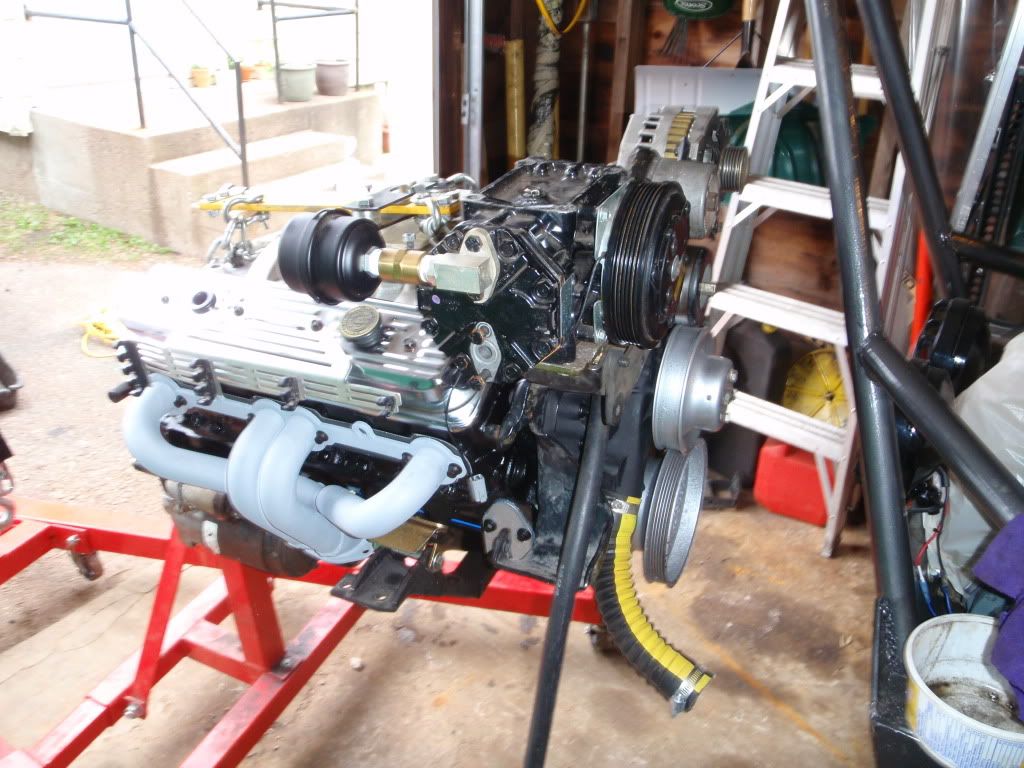

I sandblasted the headers and started putting all the ancillaries back on today:

In total, the work at the machine shop cost me $1500:

- $320 for the machine work on the block;

- $550 for the motor assembly;

- $300 for the head work; and

- $162 for parts (push rods, break-in lube, oil, filter and an oil pump shaft).

So in total, this cost me in the vicinity of $3000 for a complete, running 383. In retrospect, I probably could have bought a crate engine for a somewhat similar price, but oh well :flipoff:

If all goes well, I should have the engine back into the frame on Sunday. The re-installation of the motor is definitely going a bit quicker than the removal

I'm hoping to have it ready to fire up for cam break-in by Thursday at the latest....

If anyone in the Petawawa / Pembroke area is looking for an automotive machine shop, I definitely recommend Brown's Auto Supplies in Pembroke (613)732-2849.

Picked up my motor on Wednesday. When I picked it up, I found out that it was a good call on my part to get the machinist to go through the cylinder heads - the centre cylinders on both heads had cracks running from the exhaust valve seats out toward the EGR ports. I didn't bring my camera with me to the machine shop, but the arrows show where they were:

The machinist told me he found another set of the same casting heads and freshened them up for me. The icing on top of the cake was that he didn't even charge me for the replacement heads :smokin:

He even shrink-wrapped the motor to keep it clean:

I sandblasted the headers and started putting all the ancillaries back on today:

In total, the work at the machine shop cost me $1500:

- $320 for the machine work on the block;

- $550 for the motor assembly;

- $300 for the head work; and

- $162 for parts (push rods, break-in lube, oil, filter and an oil pump shaft).

So in total, this cost me in the vicinity of $3000 for a complete, running 383. In retrospect, I probably could have bought a crate engine for a somewhat similar price, but oh well :flipoff:

If all goes well, I should have the engine back into the frame on Sunday. The re-installation of the motor is definitely going a bit quicker than the removal

I'm hoping to have it ready to fire up for cam break-in by Thursday at the latest....

If anyone in the Petawawa / Pembroke area is looking for an automotive machine shop, I definitely recommend Brown's Auto Supplies in Pembroke (613)732-2849.

Last edited:

blueguy

Jackstand Racer

'Nother update:

Finished re-accessorizing the motor including adding a little flair here and there:

Got the motor back into the frame rails this past weekend with help from the Missus. Took my time bolting everything up and reconnecting it all as I only wanted to do this once:

Got everything back together last night, set the distributor, and nervously hit start.

Turned and turned and turned.....then backfired big time out the air cleaner but would not catch. issed: I re-checked everything to ensure I hadn't messed anything up and tried again.........still would not start

issed: I re-checked everything to ensure I hadn't messed anything up and tried again.........still would not start

By this time, a buddy of mine from work had stopped by, so I called it a night so that I could troubleshoot with a clear head this morning.

Went back out this morning and rechecked everything - except this time instead of using the positioning of the #1 cylinder valves and piston to ensure the distributor was in line with TDC, I used the timing tape on the harmonic balancer. Wouldn't you know it - according to the timing tape, my distributor was 180* out - figures :lmao:

Fixed my dumbassed move, ensured all the wires were run properly, and hit start again. Fired up on the first turn :smokin:

As per the engine shop's directions, I idled the motor at ~2000RPM for 20 mins or so to start the cam break-in. It also gave me a good chance to check for leaks - which there didn't end up being any.

The only issue I see right now, is there is an awful lot of ticking coming from the right cylinder bank, but I haven't narrowed it down yet to either ticking lifters or maybe the header is leaking a bit.

In any case - got to run a front two piece driveshaft as well as a couple more things to finish up, and then that is it for mods until winter so I can actually wheel it this year :heep:

I'm hoping to have this thing ready for it's shakedown run in the next two weeks...

Finished re-accessorizing the motor including adding a little flair here and there:

Got the motor back into the frame rails this past weekend with help from the Missus. Took my time bolting everything up and reconnecting it all as I only wanted to do this once:

Got everything back together last night, set the distributor, and nervously hit start.

Turned and turned and turned.....then backfired big time out the air cleaner but would not catch.

By this time, a buddy of mine from work had stopped by, so I called it a night so that I could troubleshoot with a clear head this morning.

Went back out this morning and rechecked everything - except this time instead of using the positioning of the #1 cylinder valves and piston to ensure the distributor was in line with TDC, I used the timing tape on the harmonic balancer. Wouldn't you know it - according to the timing tape, my distributor was 180* out - figures :lmao:

Fixed my dumbassed move, ensured all the wires were run properly, and hit start again. Fired up on the first turn :smokin:

As per the engine shop's directions, I idled the motor at ~2000RPM for 20 mins or so to start the cam break-in. It also gave me a good chance to check for leaks - which there didn't end up being any.

The only issue I see right now, is there is an awful lot of ticking coming from the right cylinder bank, but I haven't narrowed it down yet to either ticking lifters or maybe the header is leaking a bit.

In any case - got to run a front two piece driveshaft as well as a couple more things to finish up, and then that is it for mods until winter so I can actually wheel it this year :heep:

I'm hoping to have this thing ready for it's shakedown run in the next two weeks...

Awsome, Thats looks sweet! Can't wait to see it.

:beer:

:beer: