Make sure it is a 231 and not a 242, they have different yokes

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

231/Dana 300 Doubler Build

- Thread starter 2Greys

- Start date

Yep I do! Come out and get it in the morning, I should be here

Will do! Probably leave here after 9Am. Got your address

Last edited:

Determine how much of the spline is showing. Look at the female side and see in reality most of the time it is not a very big contact patch and make sure that you have enough of the male side to allow for flex.

Determine how much of the spline is showing. Look at the female side and see in reality most of the time it is not a very big contact patch and make sure that you have enough of the male side to allow for flex.

I vaguely remember where it used to show and it looks to be about a 2" difference. Before I couldn't see the blue part of the male and now I am seeing about an inch and a quarter. Dropping it off tomorrow at Ottawa Driveshaft.

The new control box for the speedometer shipped yesterday (well the number was created at least).

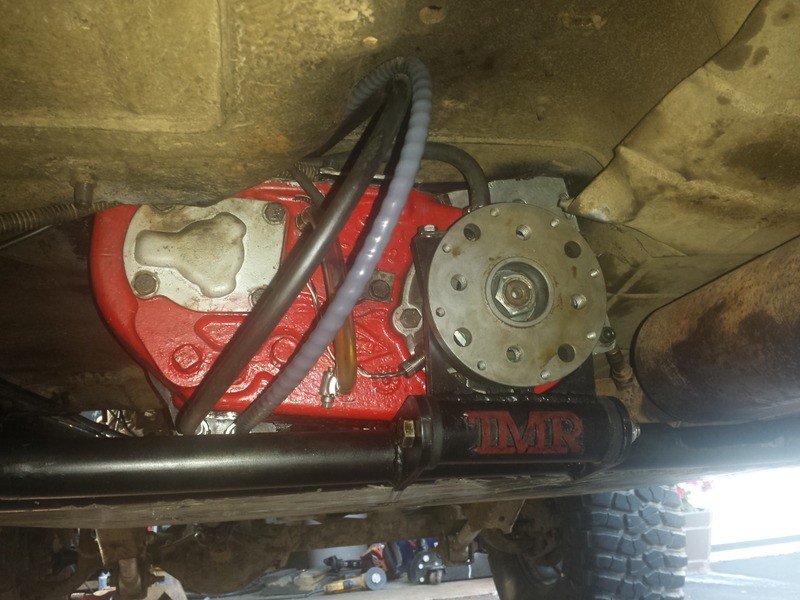

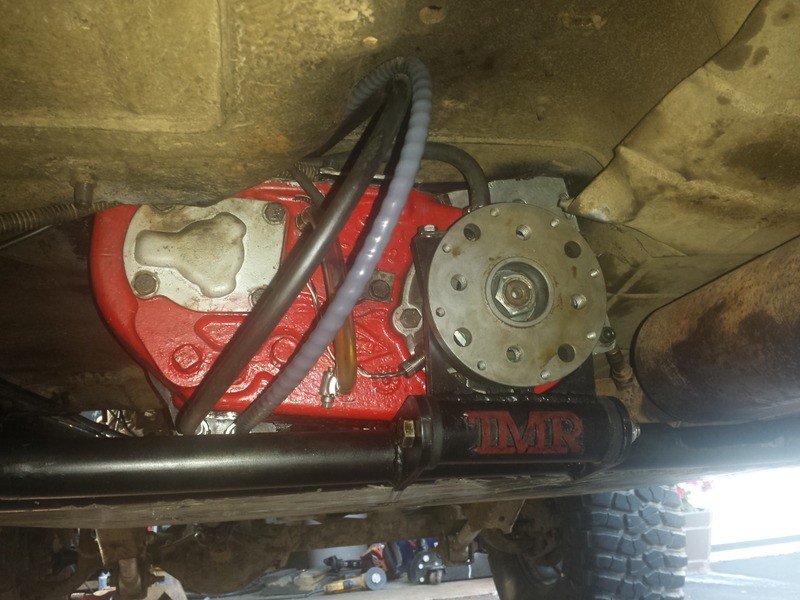

Need some advice. The Novak output is different shaped than both the Atlas and the stock Dana 300, it actually has a wider diameter but is also narrower lip. So when I got the Atlas support ring from TMR which should work with both I had to widen it by about 1/16 to 1/8" and also angle the inner side so it could sit more flush and away from the flange the driveshaft attaches to.

My concern is that with the bushing may rotate and this may force the ring off of the output and lean up against the flange. What I was thinking of doing was making a small bracket that will attach to the top of the support ring and then attach it to case itself. I was thinking one of the cover bolts.

Good idea?

Need some advice. The Novak output is different shaped than both the Atlas and the stock Dana 300, it actually has a wider diameter but is also narrower lip. So when I got the Atlas support ring from TMR which should work with both I had to widen it by about 1/16 to 1/8" and also angle the inner side so it could sit more flush and away from the flange the driveshaft attaches to.

My concern is that with the bushing may rotate and this may force the ring off of the output and lean up against the flange. What I was thinking of doing was making a small bracket that will attach to the top of the support ring and then attach it to case itself. I was thinking one of the cover bolts.

Good idea?

Got all of the shifters working today. The doubler one is pretty stiff though but what I did was cut the spring down a bit. It is still stiff but can still be changed. I have a spare intact spring if I find it ends up being easier to change when moving a bit.

Get driveshafts tomorrow, the front ended up having an extra 2.5" added.

Started building a small bracket out of 1/8" steel. It will bolt to the rear two bolts on the passenger side and connected to another small bracket attached to the bolt holes that the bracket ring uses. This should alleviate my fears of the support ring shifting off the rear output.

Get driveshafts tomorrow, the front ended up having an extra 2.5" added.

Started building a small bracket out of 1/8" steel. It will bolt to the rear two bolts on the passenger side and connected to another small bracket attached to the bolt holes that the bracket ring uses. This should alleviate my fears of the support ring shifting off the rear output.

Last edited:

mucovich

Till Valhalla!

The new control box for the speedometer shipped yesterday (well the number was created at least).

Need some advice. The Novak output is different shaped than both the Atlas and the stock Dana 300, it actually has a wider diameter but is also narrower lip. So when I got the Atlas support ring from TMR which should work with both I had to widen it by about 1/16 to 1/8" and also angle the inner side so it could sit more flush and away from the flange the driveshaft attaches to.

My concern is that with the bushing may rotate and this may force the ring off of the output and lean up against the flange. What I was thinking of doing was making a small bracket that will attach to the top of the support ring and then attach it to case itself. I was thinking one of the cover bolts.

Good idea?

I don't see an issue with making the bracket you are talking about.

Good because I already started

Right now it is covering both bolts on the ring and will attach to the back two but not the side one as the vent runs out the top of the output and it would get in the way. Making it out of 1/8 steel so it should be stiff enough.

Right now it is covering both bolts on the ring and will attach to the back two but not the side one as the vent runs out the top of the output and it would get in the way. Making it out of 1/8 steel so it should be stiff enough.

Last edited:

Got the driveshafts.

Ottawa Driveshaft was able to built it with 1350s by using Neapco parts rather than Spicer. There is at least 5" of travel but I need to see if there is any binding. Easiest way is to drop the axle to full droop and then try attaching to the diff. I also need to pick up some bolts where the rear driveshaft attaches to the Dana 300 as it didn't come with them. Will contact Novak but I think typical Grade 8 bolts should work.

So I got the front drive shaft on, the skid and the crossmember.

You can see how snug things are. Yes the rear cables stick out a bit but they should be ok where they are and you are dealing with the radius that cable shifters can take.

View from the back

Crossmember sits above the skid line just.

All that is left is:

- mounting rear drive shaft

- finishing little retainer bracket for the support ring to make sure it doesn't slip off due to the narrowness of the ring on the Novak

Ottawa Driveshaft was able to built it with 1350s by using Neapco parts rather than Spicer. There is at least 5" of travel but I need to see if there is any binding. Easiest way is to drop the axle to full droop and then try attaching to the diff. I also need to pick up some bolts where the rear driveshaft attaches to the Dana 300 as it didn't come with them. Will contact Novak but I think typical Grade 8 bolts should work.

So I got the front drive shaft on, the skid and the crossmember.

You can see how snug things are. Yes the rear cables stick out a bit but they should be ok where they are and you are dealing with the radius that cable shifters can take.

View from the back

Crossmember sits above the skid line just.

All that is left is:

- mounting rear drive shaft

- finishing little retainer bracket for the support ring to make sure it doesn't slip off due to the narrowness of the ring on the Novak

Nice!

Got the driveshafts.

Holy crap, and I thought the CJ had a short rear drive shaft.

Looks good, I'm sure you'll be happy to finally have it done, and done right.

Holy crap, and I thought the CJ had a short rear drive shaft.

Looks good, I'm sure you'll be happy to finally have it done, and done right.

Done right would be extended wheelbase but I digress. It is short but it has a really long shaft (that's what she said).

The good news,

jacked it up and dropped the axle to full droop and there would be no binding with the new driveshaft.

The bad news. It looks like 1350 based driveshafts expect to be attached to the flange with the bolt attached to the rear of the flange rather than through the front like a Ford 8.8. Is this right? Well if it is, I have serious problems since the support ring is right there.

My choices right now are:

- don't use crossmember for now and figure out how to make a bracket that will attach to the output. I may be able to get some dimensions from Novak that I can use and have Mike Lorint fab it up. I could then dick with the crossmember and see if I can mount on the back of the existing mount or move the crossmember out a bit and flip the bracket to the back

- Forgo the 1350 and go back to a 1310 based driveshaft and beg and plead Ottawa Driveshaft to give credit in exchange.

- Contact Novak and see if maybe they were supposed to be threaded. Seriously doubt that was the case.

jacked it up and dropped the axle to full droop and there would be no binding with the new driveshaft.

The bad news. It looks like 1350 based driveshafts expect to be attached to the flange with the bolt attached to the rear of the flange rather than through the front like a Ford 8.8. Is this right? Well if it is, I have serious problems since the support ring is right there.

My choices right now are:

- don't use crossmember for now and figure out how to make a bracket that will attach to the output. I may be able to get some dimensions from Novak that I can use and have Mike Lorint fab it up. I could then dick with the crossmember and see if I can mount on the back of the existing mount or move the crossmember out a bit and flip the bracket to the back

- Forgo the 1350 and go back to a 1310 based driveshaft and beg and plead Ottawa Driveshaft to give credit in exchange.

- Contact Novak and see if maybe they were supposed to be threaded. Seriously doubt that was the case.