Yes you can do that. :beer: Have had this discussion the force is the same anywhere on the wheel. I will just end up with possibly more dirt entering the brakes, especially mud, unless you were going back and forth in the mud lol. Oh make sure your pads are bevelled on both ends though, they usually are.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yello

- Thread starter O.D.

- Start date

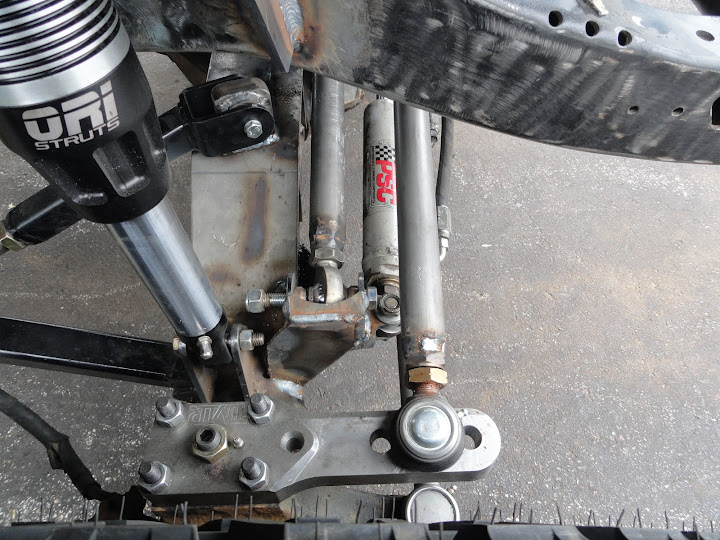

So, i am having a fakk of a time getting good clearance on the rear for the ORI's and the CC 14Bolt. I have the bottom shock mount outward as much as i can before i hit the drum flange mount and on the top, i have the tower frenched into the frame as much as i can and i am still having clearance issues on droop.

what's the consensus on partially grinding off the flange on the back of the axle? If i can get that out of the way, i can then dump the bottom shock mount out another inch or so and that will give me more than enough clearance...

Any issues doing this?

Cheers,

what's the consensus on partially grinding off the flange on the back of the axle? If i can get that out of the way, i can then dump the bottom shock mount out another inch or so and that will give me more than enough clearance...

Any issues doing this?

Cheers,

i don't have pics right now..

Since it is a CC 14b, when converting to Discs running a SRW, you have to offset the rotor a fair amount. Options are get custom bracket that moves the caliper outwards that mounts to the existing flange or get custom brackets that weld directly to the tube, between the flange and the spindle. The latter is what is currently on my axle. However the flange is still present. Because of that, i cannot effectively mount my lower shock mount outwards as much as i want to have the ORI leaning inwards towards the top.

To add to the mess, the current caliper bracket that is welded to the tube is setup to have the caliper at the back of the rotor. Again because of clearance, i have to move the calioper to the front of the rotor.

So, my perfect scenario is to cut/grind off the back side of the wraparound OE drum brake flange (Retain the front side of the flange to mount my new CC caliper mounts that i have ordered so that i can spin the caliper to the front of the rotor). Then also remove the existing caliper mount that was welded to the tube when the 14b was originally converted to discs....

My concern lies in removing half of the existing OE drum flange.. I just want to make sure that doing so will not weaken the tube. I have yet to find any info on this..

Since it is a CC 14b, when converting to Discs running a SRW, you have to offset the rotor a fair amount. Options are get custom bracket that moves the caliper outwards that mounts to the existing flange or get custom brackets that weld directly to the tube, between the flange and the spindle. The latter is what is currently on my axle. However the flange is still present. Because of that, i cannot effectively mount my lower shock mount outwards as much as i want to have the ORI leaning inwards towards the top.

To add to the mess, the current caliper bracket that is welded to the tube is setup to have the caliper at the back of the rotor. Again because of clearance, i have to move the calioper to the front of the rotor.

So, my perfect scenario is to cut/grind off the back side of the wraparound OE drum brake flange (Retain the front side of the flange to mount my new CC caliper mounts that i have ordered so that i can spin the caliper to the front of the rotor). Then also remove the existing caliper mount that was welded to the tube when the 14b was originally converted to discs....

My concern lies in removing half of the existing OE drum flange.. I just want to make sure that doing so will not weaken the tube. I have yet to find any info on this..

mucovich

Till Valhalla!

As long as your doing the weld to tube caliper bracket I don't see a problem messaging the flange to fit the lower brackets (sounds like the flanges are not being used for anything anymore). I am sure there would be no strength lost whatsoever in axle, after all I believe those tubes are 1/2". as long as you're just removing the flange material and not touching the tube or area where the spindle is welded to the tube I believe you should be good to go. Is there any way to modify the lower shock bracket to fit onto both the flange and axle, (so it welds to the flange and axle)? if that makes sense

Here are a couple of pics i got..

I can' really mod the shock bracket as i think the flange will still get in the way on full articulation. My plan would be to cut the back half off of the flange, cut off the existing welded on caliper bracket (Which you can see between the flange and rotor). Then utilizing the front half of the flange mount the new CC SRW caliper brackets i have on the front side of the axle and then even go so far as to weld it to the flange.

That should give me the clearance on the back and the calipers on the front of the rotors.

mucovich

Till Valhalla!

ahh, now I see. I didn't realize you were using that type of mount for the shocks. I does look as if your plan to modify the flange to push that mount out would work. It's too late now but using a more traditional mount on the top side of the axle looks like would have worked with no problems, but I'm sure your upper mount is positioned to work with this style. Is the tube on the outboard side of the flange pressure welded at the flange or is it the same piece of tube? If the tube is a solid piece I say do it, anyone else?

Thanks Marek

I wanted to do top sided axle mounts for the shock but i would end up having to limit my uptravel by having to keep it at a certain ride height (To get in and out of the shop!!) and i didn't see how i'd get a good line with the frame sided mount.

In any event, i went ahead and cut the flange.....

And Fakkin' A!! i finally have a corner properly lined up with full clearance throughout travel!! I have about 7" uptravel before i stuff the 40's and 7" downtravel with full clearance throughout... Now that i have the correct position, the other side on the back should be much faster. The only thing really left to do then on the back for suspension is to setup the calipers on the front of the rotors.

I wanted to do top sided axle mounts for the shock but i would end up having to limit my uptravel by having to keep it at a certain ride height (To get in and out of the shop!!) and i didn't see how i'd get a good line with the frame sided mount.

In any event, i went ahead and cut the flange.....

And Fakkin' A!! i finally have a corner properly lined up with full clearance throughout travel!! I have about 7" uptravel before i stuff the 40's and 7" downtravel with full clearance throughout... Now that i have the correct position, the other side on the back should be much faster. The only thing really left to do then on the back for suspension is to setup the calipers on the front of the rotors.

Shoot.. Forgot about those. I'll contact George to pay him  If you don't mind holding on to them for a bit, i am in rush right now to get them. Unless they are in your way...

If you don't mind holding on to them for a bit, i am in rush right now to get them. Unless they are in your way...

I am anxious for sure but am nowhere near doing that unfortunately. I haven't even started to tackle the front or the engine

Had a few setbacks over the past month that has taken up allot of my time. Hopefully things will settle in and i'll have more shop time moving forward.

I am anxious for sure but am nowhere near doing that unfortunately. I haven't even started to tackle the front or the engine

Had a few setbacks over the past month that has taken up allot of my time. Hopefully things will settle in and i'll have more shop time moving forward.

Had a good morning!! Ended up trimming the hood to fit the highline fenders. Turned out not bad. Had to take about 3" all along the edge. Some of the cross channels then had to be sanded down to give proper clearance. I am just going to run door edge trim along the cut (Picked some up at Cdn Tire).

Also was able to flip the caliper on one side of the 14 bolt. What a pain it was to get the existing caliper bracket off.. The new bracket bolted to the existing drum flange. Because i had already ground off the back of the flange to clear the rear shock mount, i had to cut off a bit of the bracket and only run 3 bolts to mount instead of 4. I don't see it has a problem though..

Pics:

Also was able to flip the caliper on one side of the 14 bolt. What a pain it was to get the existing caliper bracket off.. The new bracket bolted to the existing drum flange. Because i had already ground off the back of the flange to clear the rear shock mount, i had to cut off a bit of the bracket and only run 3 bolts to mount instead of 4. I don't see it has a problem though..

Pics:

Sweet!

Little update... So, i decided to spend my tax return on something i never would do. But in the end, i looked at how much work i had left and then looked at how much time i had coming up and with summer approaching...

Front is done!! I decided to farm it out to National in Smith Falls for putting together the front end for me as I had little to no time to do so... Very very beef!!! Everythings just loosely bolted together and i have not yet set ride height... Those will come. For now, it is ready for full tear down again for hopefully the last time, fix the hole in the floor, start sanding/primer/paint basically everything, final welds, fuel, cooling, TC support bracket, flip the other rear caliper, sway bars, setup shifters for tranny and TC, start work on the engine wiring, tranny cooler, driveshafts, exhaust, finish hydro assist setup and a shit load of misc items... Yeah.... We're almost there !!!!

Front is done!! I decided to farm it out to National in Smith Falls for putting together the front end for me as I had little to no time to do so... Very very beef!!! Everythings just loosely bolted together and i have not yet set ride height... Those will come. For now, it is ready for full tear down again for hopefully the last time, fix the hole in the floor, start sanding/primer/paint basically everything, final welds, fuel, cooling, TC support bracket, flip the other rear caliper, sway bars, setup shifters for tranny and TC, start work on the engine wiring, tranny cooler, driveshafts, exhaust, finish hydro assist setup and a shit load of misc items... Yeah.... We're almost there !!!!